Over the last few months, the issue of plastic waste has been at the forefront of industry discussion, from conferences such as Responsible Packaging Expo and Plastic Waste Free World, to UK legislation.

The waste produced in food packaging, which relies heavily on polluting flexible films and plastic coatings, has been one of the main topics of discussion.

Consumer research by Xampla has also found that the public are unaware of the use of plastics in some of these applications, with 60% not being aware of plastic coatings on cardboard for food packaging.

Proud to speak at both Responsible Packaging Expo and Plastic Waste Free World, I explained to the attendees the traditional practices that take place.

For example, paper and cardboard takeaway boxes are commonly coated in either petrochemical-based or fluorochemical materials or per- and polyfluoroalkyl substances (PFAS), to protect and preserve produce.

Traditionally applied as coatings, petrochemical-based or fluorochemical materials are neither compostable nor recyclable, and these coatings disrupt recycling systems, polluting the natural environment.

Commonly used alternatives include per and polyfluoroalkyl substances (PFAS) or ‘forever chemicals’. Despite these synthetic materials making packaging resistant to grease, liquids, and heat, they have concerning environmental and health implications.

As both plastics come under increasing regulatory scrutiny, in legislation such as the EU Single-Use Plastic Directive, and further research explores consequences of ‘forever chemicals’, brands are looking to futureproof themselves with plant-based solutions.

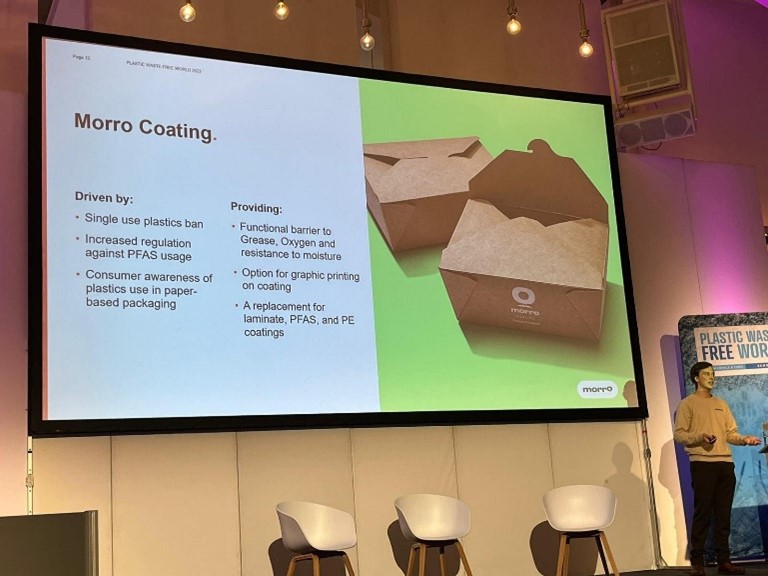

Classified as a natural polymer, Xampla’s innovation Morro Coating provides a natural solution for manufacturers and brands alike.

Attendees in London and Cologne discovered how high-performance natural coatings can be seamlessly integrated to match FMCG companies’ existing manufacturing processes and operations. This integration eliminates any logistical barriers, reducing costs for companies and offering a pathway to replace plastics today.

Powered by plants, Morro Coating replaces the need for ‘forever chemicals’ and plastic coatings on paper or cardboard packaging by offering a fully biodegradable and food safe material.

By offering impressive grease, oxygen and water barrier properties, Morro Coating provides consumers with the experience they are used to, without pollution.

The innovative technology can be applied to a variety of substrates and tailored to the needs of specific applications to deliver a sustainable packaging solution.

This is a triple-win for the environment: eliminating the reliance on ‘forever chemicals’ in food packaging, avoiding the release of synthetic polymers into the environment, and enabling the recyclability of coated paper and cardboard packaging.

Working with international manufacturers, 2M Group of Companies, Xampla are scaling up production of Morro materials to accelerate bringing this natural solution to market.

This is something consumers increasingly want too. Three-quarters of the public would prefer cardboard packaging for takeaways to be coated with natural materials, instead of plastic.

As brands increasingly recognise the need to transition away from conventional plastic coatings, Morro Coating emerges as a solution that effectively gets ahead of the curve of evolving regulatory requirements and meets consumer expectations for responsible and sustainable packaging solutions.

If you’d like to know more about Morro Coating please get in touch.